The Altus approachto growth is

to create long-term value

July 15, 2013

IIMAK President Expects Bright Future For TTR

In early October 2012, Doug Wagner was appointed president of IIMAK, a global provider of thermal transfer ribbons (TTR) and packaging technologies.

Wagner had held several executive sales positions at the company before the promotion to president. Prior to joining IIMAK, Wagner spent nine years with Avery Dennison working in their Retail Information Services Group (RIS) in various positions, the last of which was vice president of sales & marketing for the Europe, Middle East, and Africa region.

Now that Wagner has had some time to settle in to the new position, we decided to touch base with him to see how things are going. Wagner told SCAN/DCR, “Everything is excellent. The beginning of this year was slower than expected but bounced right back. We had a record second quarter and a record first half with respect to sales.”

“Our core TTR business is still producing modestly solid gains,” he continued. “And, our efforts in adjacent markets are paying off, as well.”

iiMED Division Pays Off

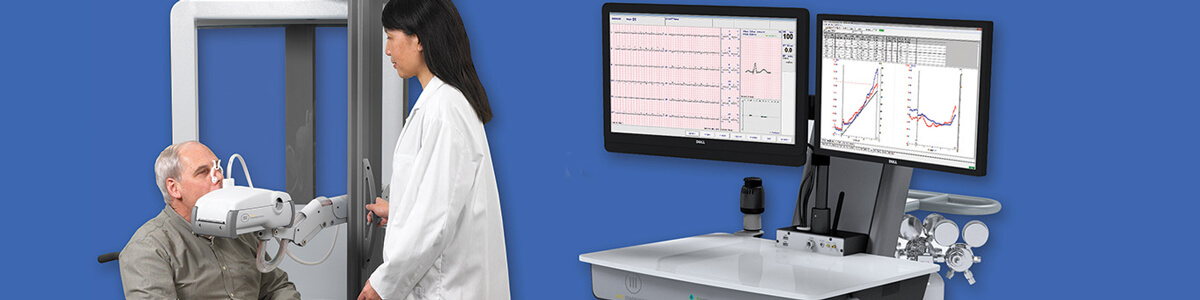

While perusing the IIMAK Web site, the company’s iiMED Medical Manufacturing Solutions division caught our attention. About 10 years ago, IIMAK opened a manufacturing site in Reynosa, Mexico. After a period of time, IIMAK leaders realized there were other ways of using their skill sets. The company evolved into the medical sector.

iiMED offers assembly and packaging services of Class I and II medical devices. Headquartered in Buffalo, New York, the state-of-the-art nearshore manufacturing operation in Reynosa is ISO 13485 certified and FDA registered.

“This part of our business has been growing in leaps and bounds,” said Wagner. “Our sales have grown 500% in the past three years, and we are currently moving to a larger facility. Our sales projections for the next three to five years are quite high.”

We asked Wagner if he could give us a few examples of the “devices” that iiMED produces. “I don’t want to give out too much information, because it might compromise our relationships with our customers,” he replied. “One example might be wraps for the treatment of deep vein thrombosis.

“This is a soup-to-nuts operation,” Wagner continued. “We cut the materials, assemble them, package them in the format chosen by the customer, and ship them to their proper destination. We offer ultrasonic and RF welding. Everything is done under stringent guidelines with respect to cleanliness and sanitization. Our customers are traditionally small- to mid-size companies. The team is bi- lingual, and the cost difference between the products we produce and those produced in China is minimal. This is quite a stretch from our core technology offering, but it is one that is really paying off.” (Learn more at www.iimedical.com.)

Constant Evaluation

Over the years, in our interviews with Dick Marshall, IIMAK chairman/CEO, we have found IIMAK to be a company that never rests on its laurels. Although it is one of the clear leaders in its core market, the company always looks for new business opportunities in adjacent markets. And sometimes, in markets that may even be more of a stretch….such as the iiMED division.

Wagner told us, “We are always looking at new ways to do things-investing in our core technologies. That is the key to our success. We are on track to have a record year in sales. In addition, we have completed two acquisitions and are assessing several other opportunities.”

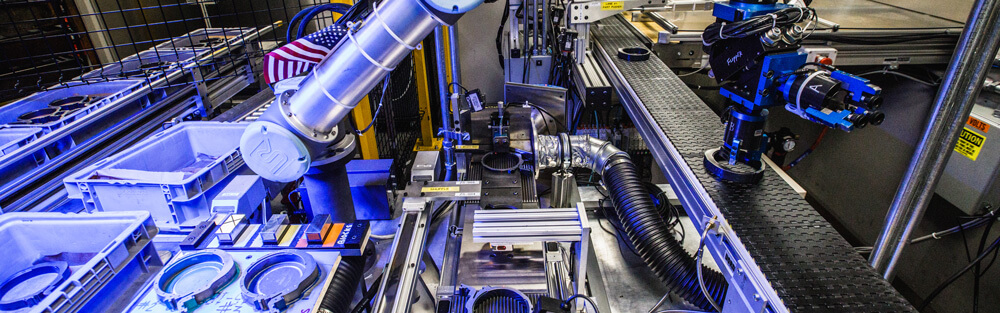

On April 25, 2013, IIMAK announced its acquisition of Graphic Controls’ inkjet ink business, effective May 1, 2013. This includes all respective manufacturing assets and processes from Graphic Controls to produce large character inks, high resolution inks, solid inks, and miscellaneous supplies.

Graphic Controls made a strategic decision to divest the inkjet business and focus on its three core market segments of industrial, medical, and transactional media. In turn, IIMAK’s strategic focus on printing, imaging, marking, and coding consumables positions IIMAK as an ideal successor for this business.

IIMAK is headquartered in Amherst, NY, a suburb of Buffalo, where the company’s ink development & production, film coating, and primary converting facilities reside. It has additional converting facilities in Mexico, Brazil, and Belgium, as well as U.S. distribution centers on the East and West Coasts.

The transition teams have been working closely to transfer knowledge, systems, and training.

On July 1, 2013, IIMAK announced its acquisition of Specialty Inks Company’s business. This includes all formulas, brands, processes, and assets from Specialty Ink Company to produce inks, stamp pads, and related items, with the exception of Mark II Stamp Pads.

Specialty Inks made a strategic decision to enact a business succession plan that provides President Gary Werwa an opportunity to take a step closer to retirement while ensuring the customer base will be supported accordingly for many years to come. In turn, IIMAK’s strategic focus on printing, imaging, marking, and coding consumables positions them as an ideal successor. IIMAK has been partners with Specialty Inks, producing a portion of Specialty’s inks for several years.

Although Gary Werwa will be moving toward retirement, and Keith Werwa will be retaining the Mark II Stamp Pad business, IIMAK said that both Gary & Keith will stay on with IIMAK for 12 months to continue to support the business. Both teams have been working closely to transfer knowledge, systems, and training to ensure a seamless transition.

“The global TTR market on its own won’t support the growth we want to achieve,” Wagner continued.

“That is why I keep going back to the statement that you must look for opportunities outside your core. Fortunately, our acquisition by Altus Capital Partners II, L.P. has provided us with the necessary funds to expand.”

Media Contact

IIMAK, Amherst, NY

(716) 691-6333 Web site: www.iimak.com.